Energy

Vapor recovery - environmental friendly and easy to handle

Consulting, development and production from a single source for economic system solutions

In many countries, vapor recovery is required by law. The aim is to return petrol vapor that escape during vehicle refueling to the storage tanks. With the help of vapor recovery systems - referred to in international expert circles as STAGE II - hydrocarbon emissions can be significantly reduced.

Active vapor recovery systems have become established on the market due to their higher efficiency and more convenient handling for the customer.

The vapor recovery pump is the decisive component for a trouble-free working vapor recovery system. With the MEX vapor recovery pump, Dürr Technik offers a high-quality and very safe solution with a constant flow rate throughout the whole lifetime.

Our quality and reliability is guaranteed by various certifications: ATEX, TÜV, QS, PTB and CN-EX.

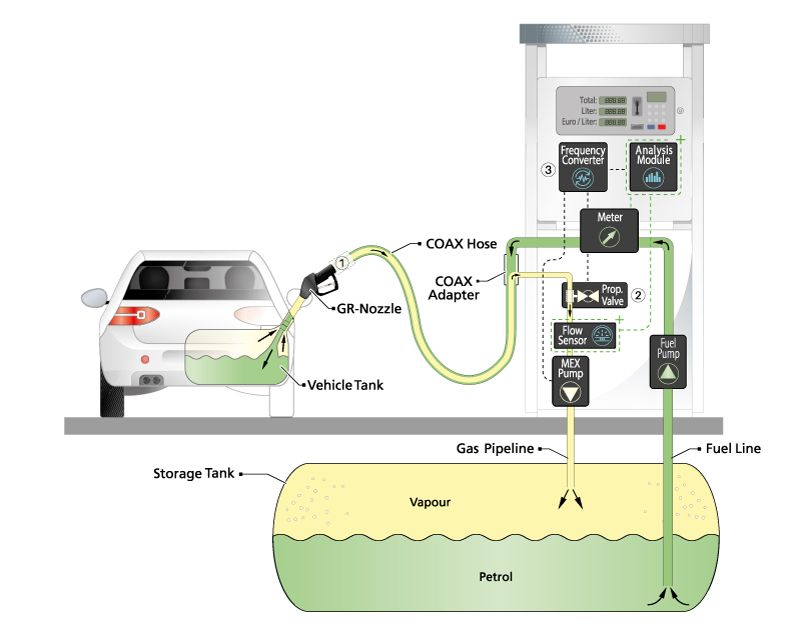

Main components of a typical vapour recovery system

How the vapour recovery system works: The function is based on the control of the volume flow ratio of fuel to extracted petrol vapour. This ratio is set to 1:1 (proportionality) and controlled by a mechanical (1) or electrical (2) proportional valve. Systems with speed control (3), like our “all in one” solution MEX Vapour Control, do not require proportional valves.

Trouble-free and economical: MEX vapour recovery pumps

Dürr Technik has been producing the MEX piston pump, specially developed for vapor recovery, since 1994. Its reliability is proven by several hundred thousand units in operation worldwide.

Legal requirements and automatic monitoring devices place the highest demands on the reliability of the vapour recovery systems. For legal reasons, the operator only has a limited period of time before the dispenser is switched off if there is a problem with the vapour recovery system. A reliable vapour recovery pump with a constant flow rate is essential for a trouble-free vapour recovery system.