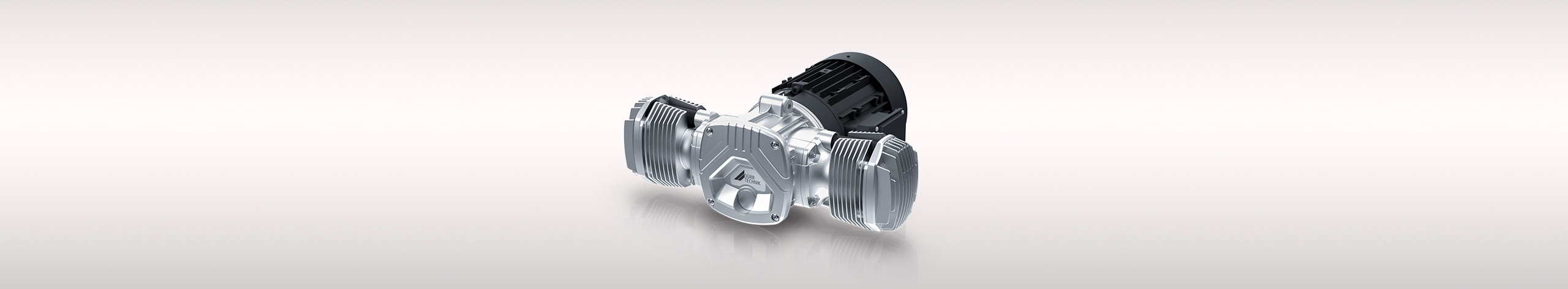

Oil-free Compressors E-Bull Series

Our small powerful compressor package for commercial vehicles, rail vehicles and a wide range of industrial applications

With the next generation of the E-Bull, Dürr Technik is optimising its innovative range of oil-free piston compressors, which are specially designed for rail and commercial vehicles such as trains, trucks and buses and as well as for industrial applications.

In the field of mobility, where every gram counts, the low weight of the E-Bull reduces energy consumption and increases payload. With a power consumption of only 10.6 watts/l/min, the next generation oft this versatile piston compressor belongs in the upper efficiency class. Despite its high performance, it is extremely quiet and makes a significant contribution to reducing noise pollution. Thanks to its compact dimensions, the compressor can be installed anywhere in the vehicle - in any installation position.

High-quality materials and our know-how in oil-free technology ensure low-maintenance operation and an extremely long service life, which is also reflected in low life-cycle costs. The robust design of the E-Bull can withstand strong vibrations and is therefore ideal for mobile applications.

With our oil-free compressors you can fully rely on an environmentally friendly solution that combines sustainability, energy efficiency and reduction of CO2 emissions.

Press article about the new generation of compressors

Mouldi Warag, Product Manager at Dürr Technik, on the new generation of oil-free electric compressors:

“These developments might not sound like much at first, but it’s actually really impressive in the context of starting with an already very compact compressor.”

Read the press release about the new E-Bull now.

Your benefits at a glance

Robust & durable

- New: Optimized heat dissipation using new rotating head design.

- Withstands strong vibrations which makes the unit suitable for mobile applications.

- Well protected against dust and water with degree of ingress protection IP 67.

- Extremely long service life thanks to high-quality materials and low-friction oil-free technology.

- Applicationtemperature range from -40°C to +50°C.

Powerful & efficient

- New: 11% higher flow rate compared to the previous model with lower weight (depending on application only 0.1 kg per l/min).

- Suitable for operation with frequency inverter. Using a variable speed inverter allows for optimum operation of the compressor and can also lead to energy savings in the system.

- Long distance run: guaranteed 100% duty cycle.

Compact & quiet

- New: Even less space required thanks to internal air ducting.

- Variable mounting positions.

- Extremely quiet compared to other piston compressors.

Economical & environmentally friendly

- New: Even more sustainable with a 6% reduction in power consumption.

- Savings in oil, filter and waste oil disposal costs thanks to oil-free technology.

- Low life cycle costs due to low spare parts requirement.

- Low maintenance operation and extended maintenance intervals without the need for oil management.

- Environmentally friendly thanks to low energy consumption thanks to motors specially matched to the series (IE3 motor).