Drive of beer pumps for beer dispensing

Oil-free compressed air for your beer dispensing system

Best beer quality by using oil-free compressors

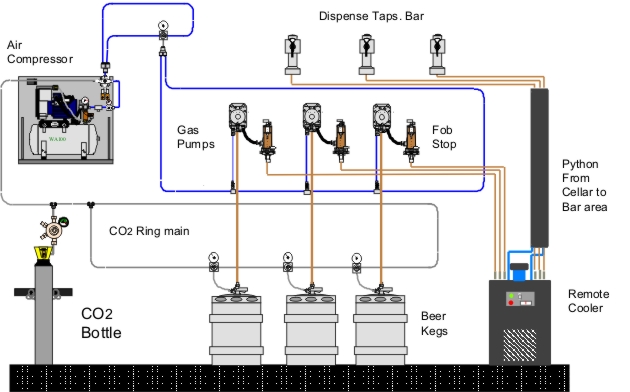

Compressed air has become a very efficient tool in the beverage industry. Oil-free compressed air is particularly economical, environmentally friendly and meets the industry`s air purity requirements. Dürr Technik`s oil-free compressors are used to operate beer dispensing systems. In these systems, compressed air drives the beer pumps to eliminate unwanted pressure buildup, thus minimizing over-carbonation and beer loss.

Compressor-driven beer pumps are environmentally friendly and significantly reduce the CO2 footprint and gas consumption.

Advantages of Dürr Technik compressors for your beer dispensing system

- Savings in gas costs

- Significant reduction in CO2 consumption

- Logistics with CO2 bottles is reduced

- Improved occupational safety

- Reduction of beer losses up to 25%

- Consistently high quality beer even with long beverage lines

- Reduces the chance to over-carbonate the beer

- Continuous and convenient tapping

- No loss in tapping times

Versatile application possibilities

Dürr Technik`s decades long expertise in oil-free compressor technology allows it to meet the requirements of a wide range of beverage and beer dispensing applications. Our comprehensive product portfolio will offer a solution for virtually every owner and operator.

Possible uses and application examples:

- All dispensing systems that are supplied with gas pumps

- Optimal yield from beer kegs

- Operating syrup pumps

- Supplying compressed air for nitrogen generators

- Bag-in-box system

- Franchise stores

- Drive of cleaning pumps

- Satellite Stores

Quality through highest air purity

Compressed air purity is an important criterion for many applications in the beverage industry and has a major impact on the quality of the end product. The compressed air used to drive the pump does not come into contact with the beer and thus protects against contamination and oxidation.

Reliable drive for your pneumatic beverage pump

In addition to bars and pubs, our oil-free compressors are also used at food courts in stadiums and movie theaters, where they prove themselves to operate reliably even in a demanding environment where a large number of customers need to be served in the shortest possible time.

When combined with a high quality beverage dispensing pump (such as a Floret or Shuffle brand), Durr Technik`s oil-free air compressors operate reliably and reach a long lifespan even during peak times. Equipped with a 3 micron filter, our products ensure that the beer pumps will never be contaminated by the supplied compressed air.

Find the various drives for your pneumatically operated beverage pump

| Type | Size of vessel in litre |

Number of pumps* | Max. dispensed volumes supported in l/min |

| UA-025 | 3 | 1 | 2 |

| WA-038 | 10 | 2 | 4 |

| TA-038 | 25 | 2 | 4 |

| TA-061 | 25 | 4 | 8 |

| TA-065 | 25 | 4 | 8 |

| TA-100C1 | 25 | 8 | 16 |

| TAG-132 | 25 | 9 | 18 |

| TA-200C1 | 25 | 16 | 32 |

Generally applies: The number of connected pumps depends on

- Cable length

- Cable diameter

- Operating pressure

- Required air volume